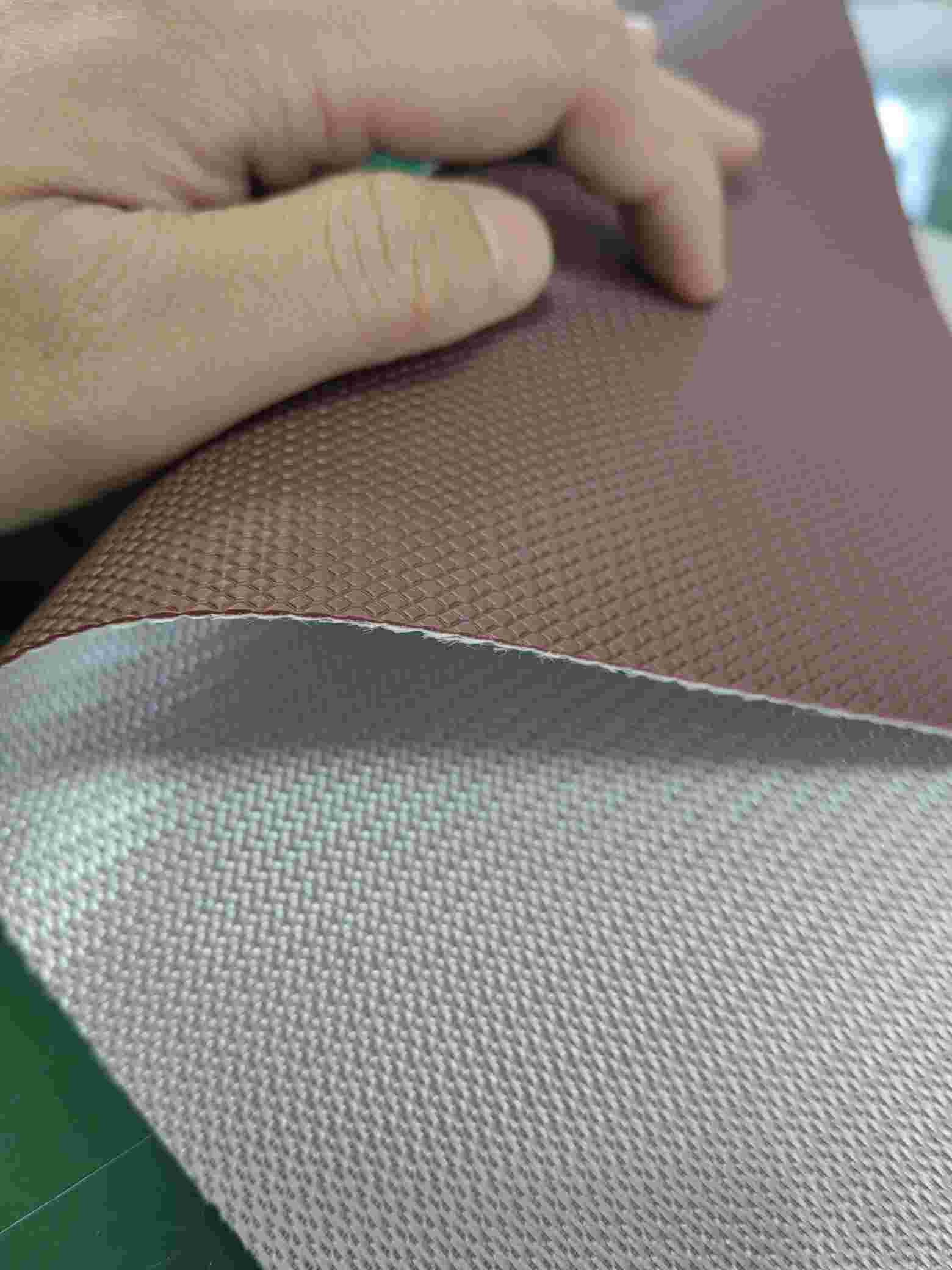

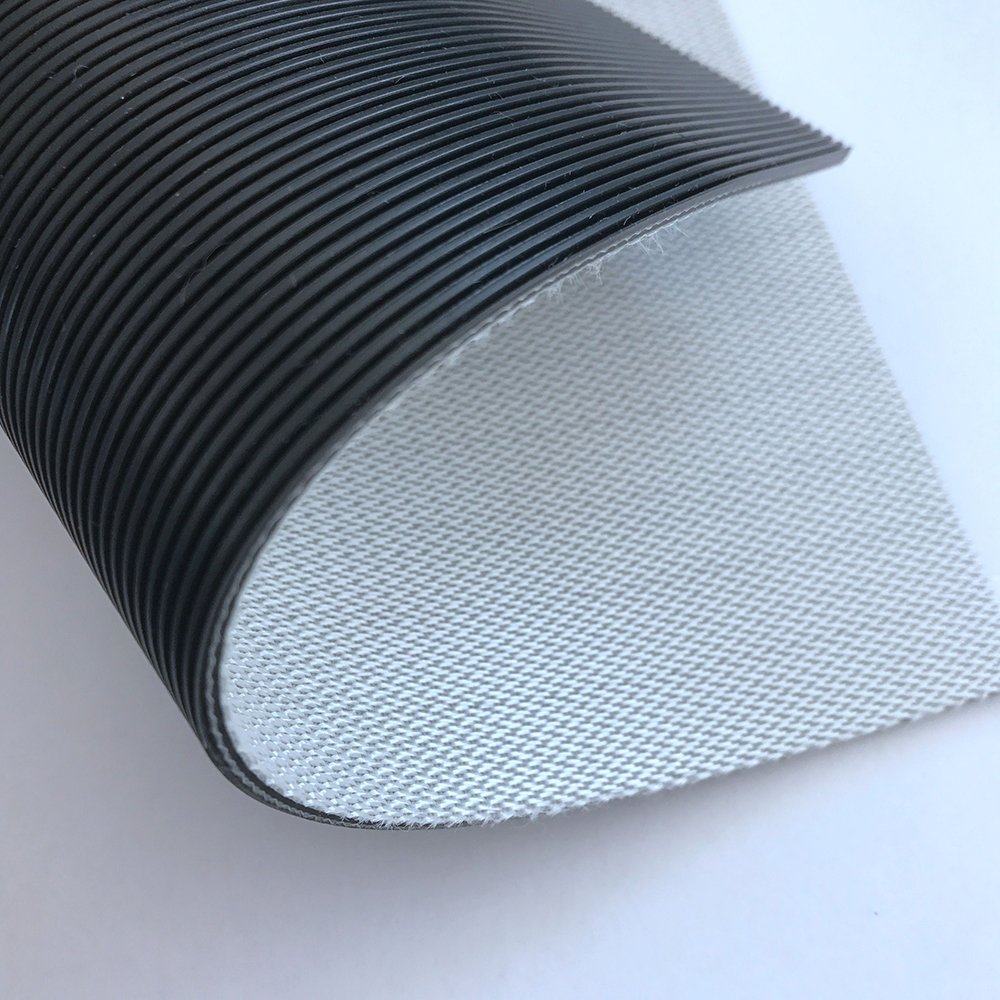

Product Overview

Our PVC Convex rhombus pattern belt for cholocate industry is a conveyor belt specially designed for the chocolate industry. It has a raised diamond-shaped pattern, which can effectively increase friction and prevent chocolate from slipping or falling during transportation. The conveyor belt is made of food-grade PVC material, meets hygiene standards, can come into direct contact with food, and is safe and hygienic.

How to use

Installation: Before installation, clean the conveyor belt and conveyor surface to ensure that they are clean and dust-free. The conveyor belt is then stretched from one end of the conveyor and gradually spread in the direction of the conveyor until it covers the entire conveyor surface. Note that the conveyor belt should be in close contact with the conveyor and must not be loose or wrinkled.

Operation: Before official use, test run first to check whether the conveyor belt is properly installed and whether it runs smoothly and without noise. Then, adjust the speed and direction of the conveyor belt as needed to ensure that the chocolate passes smoothly through the conveyor belt.

Maintenance: Check the wear of the conveyor belt regularly and replace the seriously worn parts in a timely manner. At the same time, avoid situations such as overloading the conveyor belt, reverse operation, and scratching by sharp items, so as not to affect the service life of the conveyor belt.

Maintenance

Cleaning: Clean the surface of the conveyor belt regularly to avoid dust and stains. When cleaning, clean water or neutral detergent can be used to avoid the use of corrosive substances such as strong acids and alkalis.

Lubrication: Lubricate parts such as rollers and bearings of the conveyor belt to reduce friction and wear. When lubricating, special food grade lubricant or grease should be used. The amount should not be excessive to avoid grease contamination.

Maintenance: Regularly maintain the PVC convex rhombus pattern belt for cholocate industry, check whether the structure and connectors of the conveyor belt are firm, whether there are any damage such as cracks or fractures, etc., and repair or replace them in a timely manner.

Functions of PVC Pu Conveyor Convex Rhombus Pattern Belt

The PVC Pu Conveyor Convex Rhombus Pattern Belt is engineered to perform a multitude of functions that are essential in the chocolate manufacturing process. Let’s explore these functions in detail.

Gentle Product Handling

Minimizing Product Damage: The convex rhombus pattern on the belt surface provides a secure grip on chocolate products, preventing damage that can occur with other conveyor belts.

Smooth Movement: This belt ensures that chocolates are transported smoothly and gently, reducing the risk of breakage or deformation.

Efficient Chocolate Tempering

Temperature Consistency: In chocolate tempering processes, maintaining a consistent temperature is crucial. The PVC Pu Conveyor Convex Rhombus Pattern Belt ensures even and reliable heat transfer, contributing to the quality of the final product.

Precision Timing: With precise control over the conveyor’s speed, this belt ensures that chocolates spend the optimal amount of time in each tempering phase.

Hygienic Handling

Easy Cleaning: The hygienic design of the belt surface facilitates effortless cleaning and sanitation, vital in the chocolate industry where cleanliness is paramount.

Contaminant Prevention: The absence of crevices on the belt surface reduces the risk of contaminants entering the production process.

Versatile Application

Customizable: The PVC Pu Conveyor Convex Rhombus Pattern Belt can be customized to fit various conveyor system configurations and chocolate production setups.

Multi-Stage Usage: It is suitable for use in different stages of chocolate production, from molding to cooling and packaging.

With a clear understanding of the functions, let’s explore the numerous advantages that this specialized conveyor belt offers to chocolate manufacturers.

Advantages of PVC Pu Conveyor Convex Rhombus Pattern Belt

The PVC Pu Conveyor Convex Rhombus Pattern Belt provides a plethora of advantages that can significantly impact your chocolate production process, improving efficiency, product quality, and overall profitability.

Enhanced Product Quality

Minimized Product Damage: The gentle handling of chocolates on this belt minimizes product damage, ensuring that your chocolates reach consumers in perfect condition.

Uniform Tempering: Precise temperature control during tempering processes leads to chocolates with a consistent texture and appearance.

Improved Efficiency

Reduced Downtime: The durability and reliability of this conveyor belt translate into reduced downtime due to maintenance or belt replacements.

Efficient Cleaning: Easy-to-clean surfaces reduce the time required for sanitation procedures between production runs.

Cost Savings

Longer Lifespan: The robust construction of the PVC Pu Conveyor Convex Rhombus Pattern Belt ensures a longer lifespan, reducing the need for frequent belt replacements.

Energy Efficiency: The belt’s smooth movement and minimal friction contribute to energy savings over time.

Compliance and Safety

Food Safety: The materials used in this belt are compliant with food safety regulations, ensuring that your chocolate products remain uncontaminated.

Worker Safety: A safe and hygienic working environment is promoted through easy cleaning and reduced risks of product spillage.

Now that we’ve explored the advantages, it’s essential to consider how to select the right PVC Pu Conveyor Convex Rhombus Pattern Belt for your chocolate production needs.

Choosing the Ideal PVC Pu Conveyor Convex Rhombus Pattern Belt

Selecting the right conveyor belt for your chocolate production facility requires careful consideration of several factors. Here are key considerations to guide your choice:

Belt Width and Length

Determine the required belt width and length based on your production line layout and the volume of chocolates being transported.

Surface Finish

Consider whether the convex rhombus pattern is suitable for your specific chocolate products. The belt’s surface can be customized to match your requirements.

Motor and Speed Control

Ensure that your conveyor system is equipped with the appropriate motors and speed control mechanisms to optimize the performance of the PVC Pu Conveyor Convex Rhombus Pattern Belt.

Temperature Control

Verify that the belt’s temperature tolerance aligns with the temperature conditions in your chocolate production facility, including tempering and cooling areas.

Maintenance and Cleaning

Evaluate the ease of cleaning and maintenance of the belt to streamline your production processes.

With these considerations in mind, you can make an informed choice and select the PVC Pu Conveyor Convex Rhombus Pattern Belt that best suits your chocolate manufacturing needs.

Maintenance and Care of PVC Pu Conveyor Convex Rhombus Pattern Belt

Proper maintenance and care are essential to ensure the longevity and continued performance of the PVC Pu Conveyor Convex Rhombus Pattern Belt. Here are some best practices to follow:

Regular Cleaning

Implement a routine cleaning schedule to remove any chocolate residues or debris from the belt surface. Use food-safe cleaning agents to maintain hygiene.

Visual Inspection

Regularly inspect the belt for signs of wear, damage, or misalignment. Address any issues promptly to prevent further damage and maintain efficient production.

Lubrication

If applicable, ensure that any moving parts of the conveyor system are adequately lubricated to reduce friction and wear.

Training and Safety

Train your personnel in conveyor belt maintenance and safety protocols to minimize the risk of accidents and ensure the longevity of your equipment.

Resolving common problems

What should I do if the conveyor belt is loose or wrinkled?

A: Check whether the conveyor belt is properly installed, whether it is in close contact with the conveyor, and whether it is loose or wrinkled. If there are any issues, make timely adjustments.

What should I do if the conveyor belt makes noise during operation?

A: Check whether the rollers, bearings, etc. of the conveyor belt are sufficiently lubricated and whether there is any looseness or wear. If there is a problem, make adjustments and repairs in a timely manner.

What should I do if the conveyor belt is seriously worn?

A: If the wear is severe, it is recommended to replace the conveyor belt. If a patch repair or welding repair is required, it should be handled by a professional.

What should I do if the conveyor belt is overloaded?

Adjust the speed of the conveyor belt: If the speed of the PVC convex rhombus pattern belt for cholocate industry is too fast, it may cause too much material and cause overload. Lowering the speed of the conveyor belt can reduce material input to avoid overloading.

Increase the width of the conveyor belt: If the width of the conveyor belt is insufficient, it is also easy to cause too much material and cause overload. Increasing the width of the conveyor belt can expand the space for holding materials and reduce the occurrence of overload.

Increase the number of conveyors: If only one conveyor belt cannot carry the weight or quantity of materials, the number of conveyors can be increased to distribute the weight and quantity of materials and reduce the burden on a single conveyor belt, thereby avoiding overload.

Install a deceleration device: At the end of the conveyor belt, a deceleration device can be added to slow the speed of the material, thereby reducing the occurrence of overload.

Check the operating condition of the conveyor belt: Check the operating condition of the conveyor belt regularly, including whether the conveyor belt is worn, loose, and whether there are any problems with abnormal noise. Detecting problems in a timely manner and carrying out maintenance and repairs can effectively reduce the occurrence of overloading.

If you have any further questions or need help, please don’t hesitate to contact our customer service staff. Thank you!